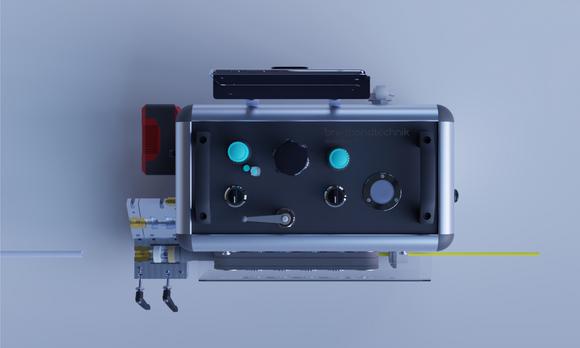

The AIRJET 300 was developed for use on all network levels; due to its performance, we recommend it primarily for network levels 1 and 2. It was the first blowing device with fully automatic monitoring of the cable surface pressure and a fully integrated pressure test unit for high-pressure tests in accordance with ZTV-40. This ensures particularly safe fiber optic installation, even on long and complicated routes. In addition, the AIRJET 300, like most other devices in the AIRJET family, features fully automatic logging in accordance with Telekom specifications.

The AIRJET 280 is used on network levels 1-3. It has the same basic functions as the AIRJET 300, but does not have the integrated pressure test and automatic logging.

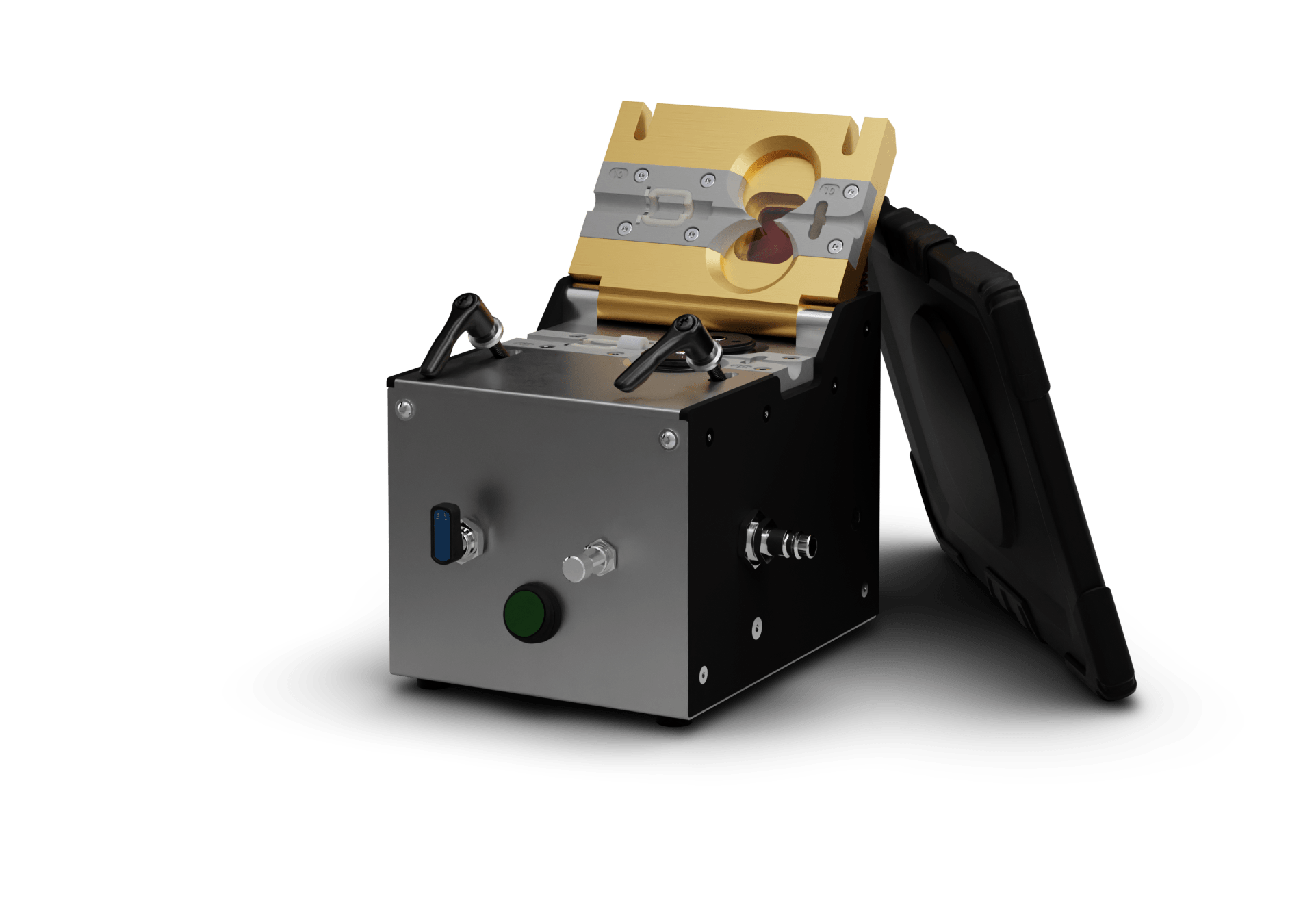

The AIRJET 100 serves network levels 3-4 and is therefore the right blowing device for laying fiber optics up to and in the building. With this machine, all house connection cables from the network distributor as well as all fibers or cables within the houses can be laid safely, quickly and without kinks. The AIRJET 100 features fully automatic logging in accordance with Telekom specifications and a fully automatic crash test function, which can be used to determine the maximum thrust force.

Like the AIRJET 300, the AIRJET 150 can be used on network levels 1-4. Its newly developed electric drive with DuoSync, in combination with the intelligent software and fully automatic logging, makes it the blowing device of the future. Its fully automatic crash test function enables even inexperienced installers to blow fiber optic cables safely.